FLUTE LAMINATED PACKAGING

An Exquisite Print Meet Strength

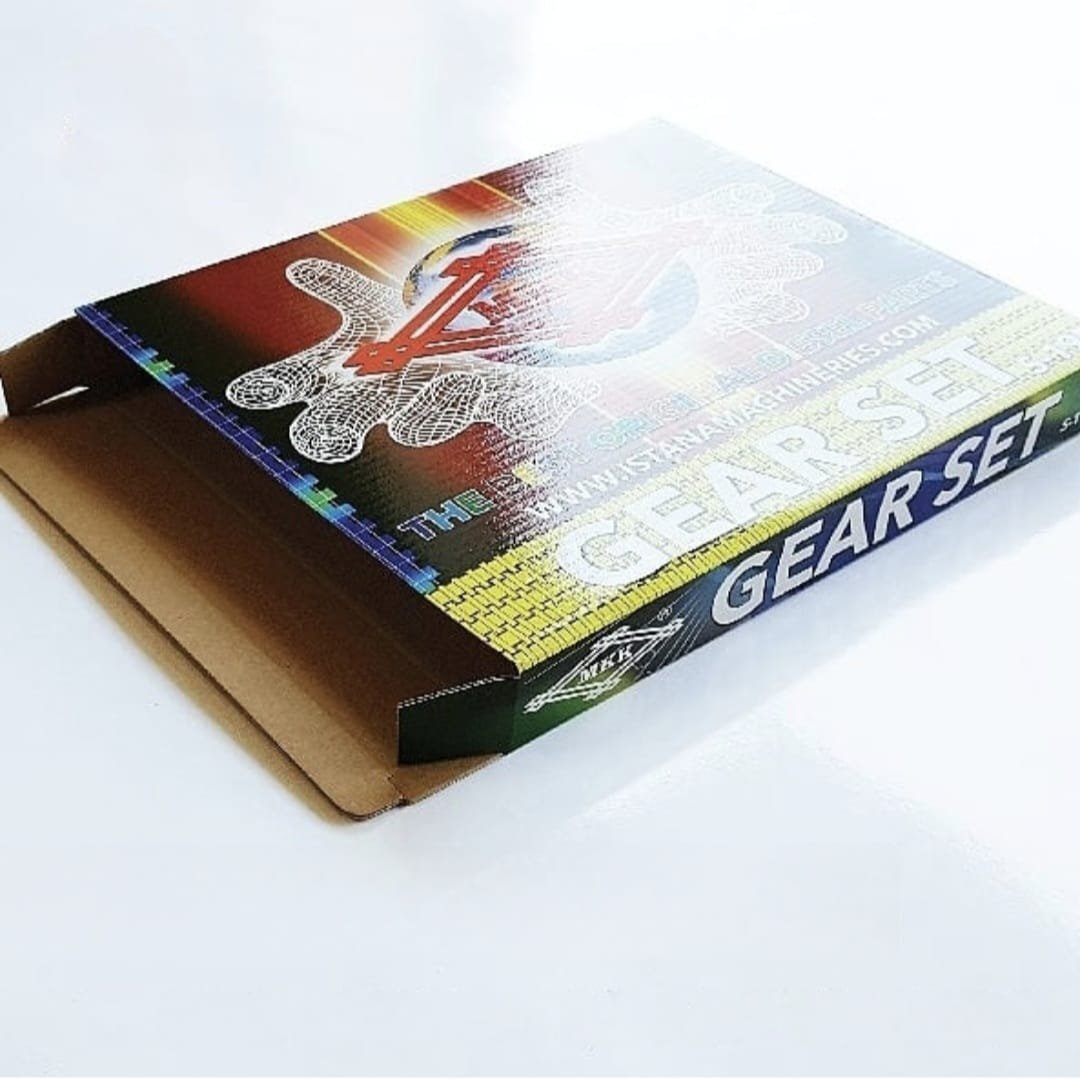

Our flute laminated boxes are made by applying a printed or flat face sheet, typically duplex paper, to a corrugated board's fluted layer, a process done using a flute laminator. The "flute" refers to the wave-like layer in corrugated cardboard, and laminating creates premium packaging with enhanced strength, cushioning, and a high-quality printable surface for branding and protection.

Why do we need corrugated flute?

Beyond combination of beauty and strength

High Quality Printing

more finishing customizations

Premium appearance

common applications

The structure of the flute laminated corrugated sheet provides strength, durability, and cushioning while remaining lightweight. Because of its unique design, corrugated packaging is ideal for shipping, retail packaging, and e-commerce.

WHY FLUTE LAMINATED PACKAGING?

Start Your Packaging Journey With Us Now

In an age where customer experience matters as much as product quality, flute laminated packaging delivers the perfect balance of practicality, sustainability, and branding opportunities. Flute laminated packaging can also add another layer of sophistication through various finishing options not available with normal corrugated packaging. Opting to add more finishing will also give a more premium vibe to your product and allows you to charge more simply because of that.